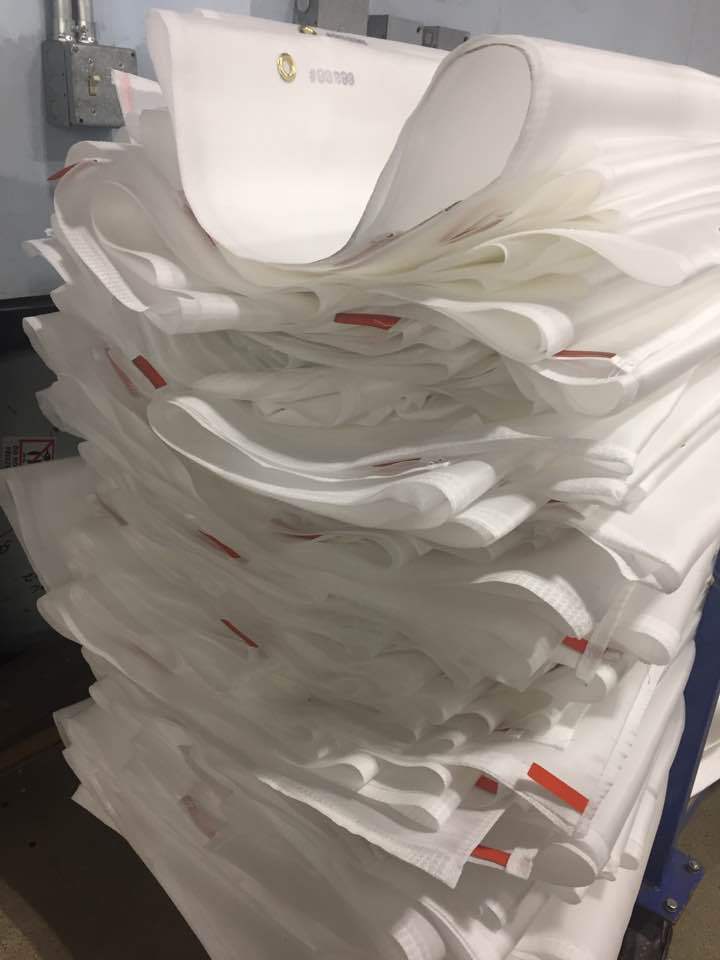

Sugar Beets are a root crop and represent over half of US sugar production. A mature sugar beet weighs 2-5 pounds and contains about 18% sucrose. The Micronics Engineered Filtration Group brings you unparalleled application expertise in the food & beverage industries including demanding industries like the recovery of sugar syrup in sugar beet processing…. Read more »