The Micronics Engineered Filtration Group is a trusted leader in high-performance Liquid Filtration products and services for the needs of demanding industries such as Alumina refineries. One of the last steps in Alumina production is the de-liquoring and washing of the alumina hydrate and Vacuum Pan Filters are typically used here.

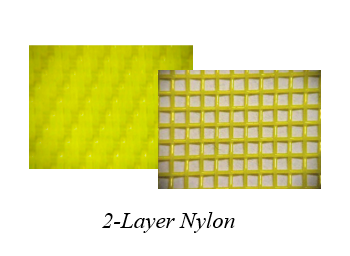

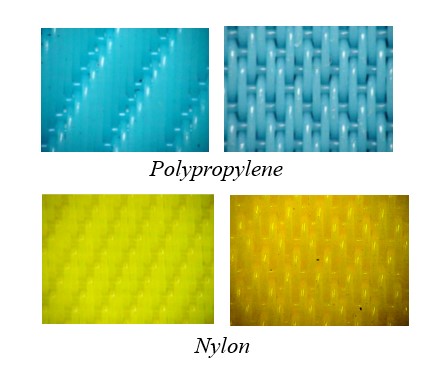

Our SOLAFT Vacuum Pan Filters are fabricated to deliver superior liquid filtration performance in highly caustic Alumina refining environments. We manufacture in state-of-the-art global facilities, with attention to detail that guarantees high quality and reliability. Our Vacuum Pan Filters can be found in Alumina Refineries with various OEMs’ innovative Pan Filter equipment.

Contact Us to learn more about our SOLAFT Vacuum Pan Filters for your demanding Alumina refining needs globally!