Filter Cloth is the key ingredient in optimizing your filter press operation. Think of our cloth as the ‘essential front line workers’ in liquid-solid separation. So, when it comes to getting the best filter press cloth for your company’s filtration needs, you can feel confident turning to Micronics.

10 Reasons Micronics is the Best Filter Cloth Manufacturer for Your Filter Press Dewatering Operation

Home > 10 Reasons Micronics is the Best Filter Cloth Manufacturer for Your Filter Press Dewatering Operation

Micronics offers standard and custom filter press cloths for all makes and models of filter presses. Benefit from our superior application expertise for your industry and operating conditions. We’ll help you navigate the filter cloth selection process so you can feel confident you are selecting the right filter cloth brand to optimize your operation.

Here are some facts about Micronics and the Micronics brand of filter cloth:

1. Reliable Production You Can Count On

Micronics has been and continues to be fully operational in both our filter media manufacturing plants during COVID-19.

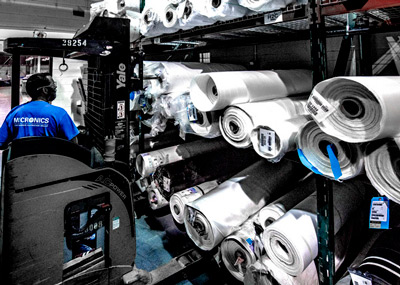

2. Extensive Inventory

Micronics maintains an extensive on-hand inventory of durable, high-performance rolled goods to meet your needs including advanced materials like Polypropylene, Nylon, Polyethylene, Polyester, and Rilsan®.

3. Diverse Specifications

Our filter cloths are available in many different materials, yarn types, and weave patterns to meet your exact filtration needs.

4. Best-in-Industry Lead Times – 2 Weeks For Custom Filter Press Cloth

Micronics utilizes several state-of-the-art laser-cutting machines to ensure fast turnaround and consistent high quality. In fact, we have worked very hard to deliver custom filter press cloth lead times that we believe truly set the standard in the industry!

5. Robust Manufacturing Capabilities in 2 plants

Micronics manufactures all of our Filter Cloth in TWO state-of-the-art filter media manufacturing facilities in Chattanooga, TN, and Saltillo, Mexico. So, we have always got your back!

6. Filter Cloth Performance Advantages You Need, Customized

Micronics works with you to deliver the filter cloth that achieves the performance advantages you need including longer cloth life, improved cake release, drier filter cakes, and generally more efficient filter press operations. Our years of textile expertise allow us to develop customized cloth recommendations for any application, including yours.

7. Knowledgeable, On-the-Ground Sales Team

In North America, Ryan, Steve, Fred, Marc, Jason, and the entire Inside Sales team are happy to assist you in filter cloth selection, considering a whole range of factors such as the need for resistance to chemical attack, tensile strength, thermal properties, and abrasion resistance so that the filter cloth you receive is precisely right for your unique set of operating conditions. In Latin America, Vlamir, Fernando, and the team are happy to assist you in cloth selection with capabilities and resources you simply won’t find anywhere else.

8. Welded “HPR” Feed Necks and “Clip Necks”

Feed necks are an important parameter that greatly affects filtration performance and Micronics offers many options from our proprietary, welded “HPR” design to a patented, Micronics-designed “clip neck.”

9. Time and Money-Saving Solutions

Micronics manufacturers filter cloth proven to save you time and money on installation vs. traditional, CGR-style cloths. Let us talk to you about new cloth solutions with no plate modifications required. Time is money and Micronics is here to improve your press efficiencies!

10. Experience in Your Markets

If you have a filtration challenge, chances are we have encountered something very similar in the diverse industries we serve including chemical manufacturing, pigments & dyes, mining & mineral processing, wastewater treatment, breweries & wineries, sugar beet processing, industrial sludge, battery recycling, commercial laundry, surface finishing, and many more industries.

Contact Us to learn more about how Micronics can meet your filter cloth needs. Order your replacement press cloths at 866.481.3694 or Request A Cloth Quote.

When you work with Micronics, we’ll help ensure you feel confident that you are selecting the right filter press cloth – and cloth manufacturer – to optimize your filter press operation! All cloth is not the same. Trust the Micronics brand.

Categories

Featured Posts

- Micronics Announces

Strategic Acquisition of

SOLAFT® Filtration Solutions - Chennai Office Inauguration

- Micronics Engineered Filtration Group Announces Strategic Acquisition of AFT®, Dry Filtration Solutions Leader, from FLSmidth

- The Power of Teamwork

- Building a High-Performance Team: Key Factors for Success

- Micronics’ CEO, Chris Cummins, Is Featured On “Manufacturing Excellence” Podcast

- Micronics Announces Large, Multi-plant Filter Press Order for Lithium-Ion Battery Recycling for EVs

- Micronics Engineered Filtration Group Announces Strategic Acquisition of Trusted Filtration Industry Leader, National Filter Media (“NFM”)

Contact Our Experts

Micronics Is Your Trusted Partner for Total Engineered Filtration Solutions. We offer end-to-end solutions from Filter Media to Industry-Leading Filtration Equipment, to Spare Parts & Accessories, to On-Site Field Services and In-House Laboratory Services. Whether for your Filter Press, Belt Press, Leaf Filter, Vacuum Filter, or Baghouse, you can count on Micronics’ deep industry and applications knowledge for the right engineered filtration solution to meet your needs. We look forward to working with your team.