The best weave for your process depends on what you are trying to achieve! Micronics’ filtration experts are happy to assist you with specifics of filter press cloth selection and ensuring you have the right filter cloth for your liquid-solid separation needs. Weave choice is but one factor in getting the performance results you require. Let’s look at the various weave patterns in some detail:

Is a Filter Press Cloth with Satin Weave Best for My Process or a Different Weave Pattern?

Contact Our Experts

Micronics Is Your Trusted Partner for Total Engineered Filtration Solutions. We offer end-to-end solutions from Filter Media to Industry-Leading Filtration Equipment, to Spare Parts & Accessories, to On-Site Field Services and In-House Laboratory Services. Whether for your Filter Press, Belt Press, Leaf Filter, Vacuum Filter, or Baghouse, you can count on Micronics’ deep industry and applications knowledge for the right engineered filtration solution to meet your needs. We look forward to working with your team.

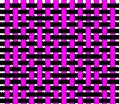

In a Satin Weave, the face of the fabric consists almost completely of warp or filling floats produced in the repeat of the weave, which causes one side of the fabric to look different than the other side. There is one filling (weft) thread, which floats over three or more warp threads, then under one. A Satin Weave is a smooth fabric surface, perhaps the most flexible of weave patterns, and conforms very easily around most contoured surfaces. Most satin weaves are four, five, eight, or twelve harness satins and are typically used where good cake release is required. Sateen is a variation produced with filling (weft) yarns. Crowfoot Satin Weave is achieved when one warp yarn weaves over three and under one fill yarn. “Crowfoot” weaves provide greater drapability than plain weave fabrics.

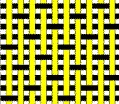

In a Satin Weave, the face of the fabric consists almost completely of warp or filling floats produced in the repeat of the weave, which causes one side of the fabric to look different than the other side. There is one filling (weft) thread, which floats over three or more warp threads, then under one. A Satin Weave is a smooth fabric surface, perhaps the most flexible of weave patterns, and conforms very easily around most contoured surfaces. Most satin weaves are four, five, eight, or twelve harness satins and are typically used where good cake release is required. Sateen is a variation produced with filling (weft) yarns. Crowfoot Satin Weave is achieved when one warp yarn weaves over three and under one fill yarn. “Crowfoot” weaves provide greater drapability than plain weave fabrics. The Plain Weave is one of the simplest weave patterns. In this type of weave, the warp and filling threads cross alternately. Plain-woven fabrics are generally the least pliable, but they are also the most stable. It has a high particle retention, low resistance to blinding, and moderate cake release properties.

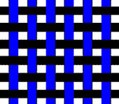

The Plain Weave is one of the simplest weave patterns. In this type of weave, the warp and filling threads cross alternately. Plain-woven fabrics are generally the least pliable, but they are also the most stable. It has a high particle retention, low resistance to blinding, and moderate cake release properties. The Twill Weave is a basic weave characterized by a diagonal rib, or twill line. Each end floats over at least two or more consecutive picks, enabling a greater number of yarns per unit area than a Plain Weave, while not losing a great deal of fabric stability. A Twill Weave has moderate resistance to blinding and moderate cake release characteristics.

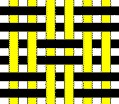

The Twill Weave is a basic weave characterized by a diagonal rib, or twill line. Each end floats over at least two or more consecutive picks, enabling a greater number of yarns per unit area than a Plain Weave, while not losing a great deal of fabric stability. A Twill Weave has moderate resistance to blinding and moderate cake release characteristics. The Basket Weave is a variation of the Plain Weave in which two or more warp yarns cross alternately with two or more filling yarns, resembling a plaited basket. This weave is more pliable and is stronger than a Plain Weave, but is looser and not as stable. The Basket Weave is typically used for backing cloths and some basic filtration applications.

The Basket Weave is a variation of the Plain Weave in which two or more warp yarns cross alternately with two or more filling yarns, resembling a plaited basket. This weave is more pliable and is stronger than a Plain Weave, but is looser and not as stable. The Basket Weave is typically used for backing cloths and some basic filtration applications. The Leno Weave is a locking-type weave in which two or more warp threads cross over each other and interlace with one or more filling threads. It is used primarily to prevent shifting of fibers in open weave fabrics and only for backing cloths. The Leno weave is typically a lightweight open-weave cloth.

The Leno Weave is a locking-type weave in which two or more warp threads cross over each other and interlace with one or more filling threads. It is used primarily to prevent shifting of fibers in open weave fabrics and only for backing cloths. The Leno weave is typically a lightweight open-weave cloth.