Sugar Beets are a root crop and represent over half of US sugar production. A mature sugar beet weighs 2-5 pounds and contains about 18% sucrose. The Micronics Engineered Filtration Group brings you unparalleled application expertise in the food & beverage industries including demanding industries like the recovery of sugar syrup in sugar beet processing…. Read more »

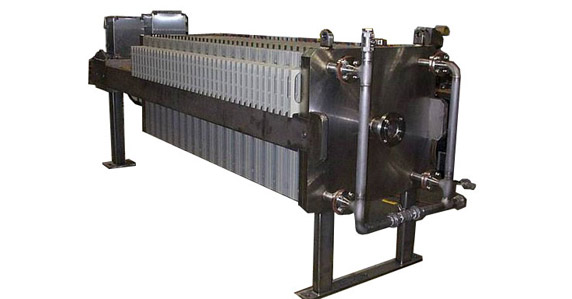

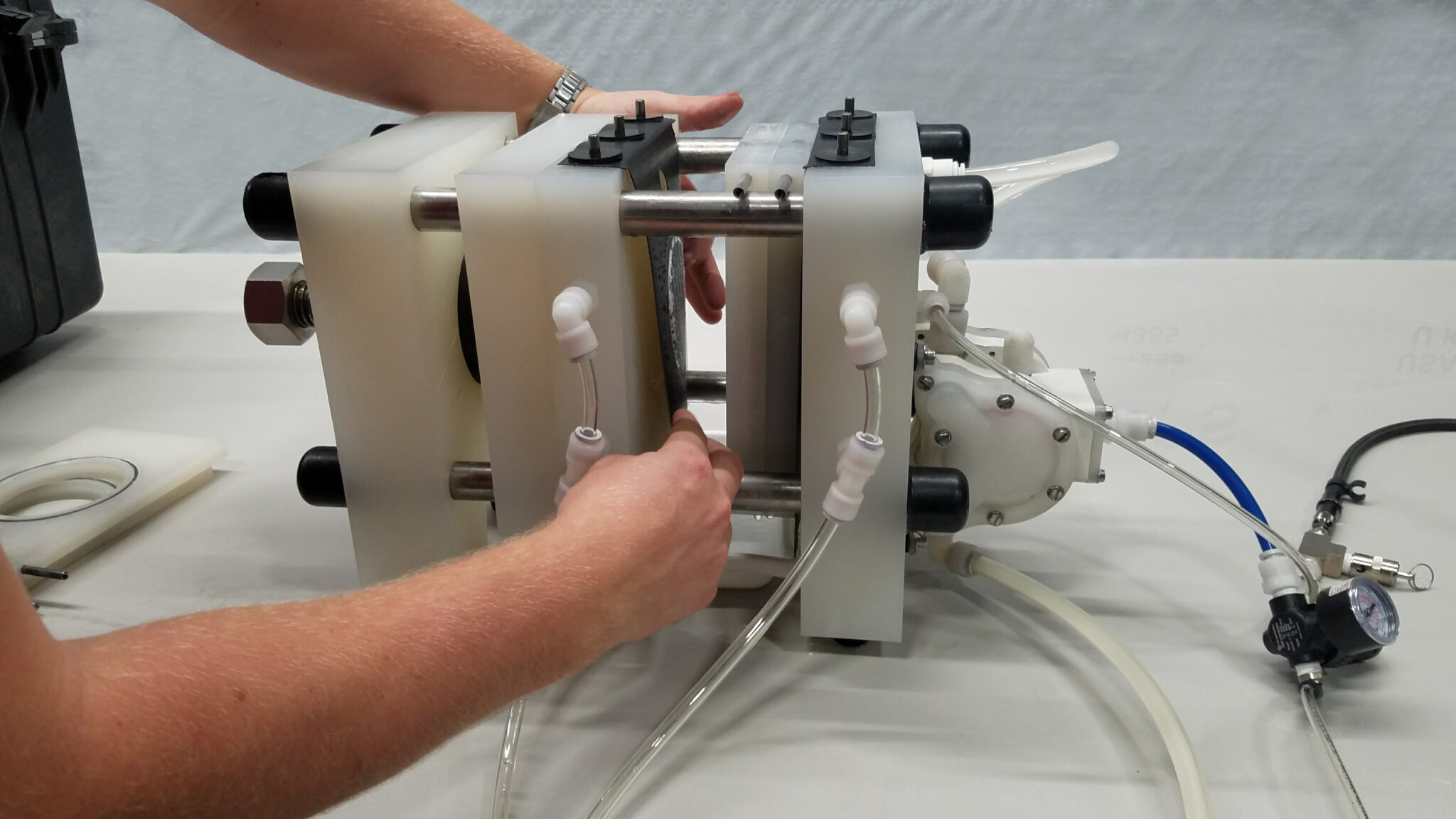

Materials of Construction and Filter Presses: Optimizing Press Designs for Your Slurry Needs

Read More »

Micronics Delivers Two Completely Customized 1500mm Filter Presses Plus Start-up & Commissioning for Leading Zinc Purification Process Plant in Latin America

Read More »

Micronics Engineered Filtration Group & Del Rey Filtros Sign Representation Agreement for Wet & Dry Filtration Products & Services in Brazil

Read More »

How Can I Ensure That I Am Getting the Right Size Filter Press for My Operation’s Needs?

Read More »