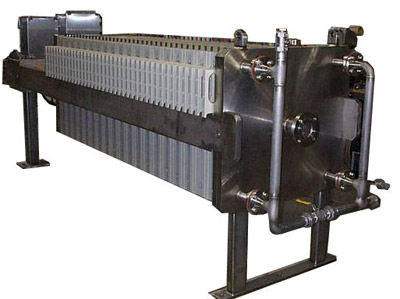

Every detail makes a difference in Filter Press engineering.

Did You Know…Material selection is a key parameter in providing you with a robust filter press design and Micronics has a keen understanding of materials of construction (MOC) design considerations.

Read the informative blog below to see what the Micronics Engineered Filtration Group can do for your operation when it comes to MOC.

Micronics is also experienced in Titanium piping. Titanium is often the material of choice in chemical processing applications due to titanium’s exceptional corrosion resistance.

Micronics is also experienced in Titanium piping. Titanium is often the material of choice in chemical processing applications due to titanium’s exceptional corrosion resistance.

Micronics offers Filter Presses which can be designed and manufactured to Food-Grade specifications, if that is your requirement.

Micronics offers Filter Presses which can be designed and manufactured to Food-Grade specifications, if that is your requirement.