At Micronics, we are often heard saying that filter cloth is the key ingredient to an efficient, effective filter press operation. Think of it as the foundation for your dewatering process. Yet, no matter the superiority of the filter cloth – and ours is pretty darn terrific – ensuring an excellent filter cloth/filter plate fit is absolutely critical for top press performance. Different cloth attachment methods are used for different situations.

What Are My Options for Filter Cloth Attachment?

Home > What Are My Options for Filter Cloth Attachment?

Cloth Attachment for Non-Gasketed Plates

Non-gasketed filter cloth and plates typically use zip ties in conjunction with rubber cloth “dog washers.” For the tops of the plates, the grommets on the filter cloth are aligned with the cloth dogs with every grommet positioned over a cloth dog. The cloth dogs are then typically secured with rubber washers. For the sides of the plates, the grommets are secured with zip ties and any excess in zip tie length can simply be clipped.

Use of Velcro® brand fasteners make for proper alignment, easy cloth repositioning, or easy release for plate inspection.

Use of Velcro® Brand Fasteners

Use of VELCRO® brand fasteners is another method for attaching filter cloth to filter plates. Use of VELCRO® brand fasteners provide a lapping joint, which has superior strength and keeps the filter cloth correctly aligned throughout the many months of the cloth’s operational life and gives “a perfect fit.” As an attachment method, use of VELCRO® brand fasteners makes for easy cloth repositioning or releasing for plate inspection or adjustment. We have found that some customers prefer the ease of installation using Velcro® brand fasteners over the use of zip ties. Additionally, it has been our experience that chemical manufacturing companies often prefer the use of Velcro vs. zip ties and dog washers to avoid even the remote possibility of plastic parts falling into the product.

Cloth Attachment for CGR Plates

For caulked and gasketed recessed filter plates –CGR filter plates – the filter cloth is actually installed in grooves within the plates using a special lightweight manual air hammer, available from Micronics. You can learn more about the use of CGR vs Non-CGR Plates and Cloth in this recent Micronics blog post.

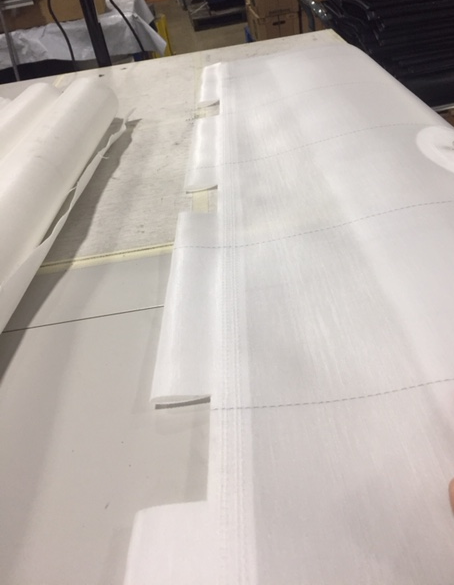

Filter cloth for rod suspension in large-scale operation shown in Micronics’ filter cloth manufacturing facilities.

Use of Rod Suspension for Cloth Attachment

Rod suspension is another cloth attachment method, commonly used in large mining and mineral processing operations. In addition, it is not uncommon for Micronics to supply filter cloths designed for rod suspension on some overhead filter presses as well as for customers who may be using older filter presses by Edwards and Jones (E&J).

Contact us to order from our extensive array of standard and custom filter cloths for virtually any filter press application from edible oils to chemical manufacturing, mining & mineral concentrates, metal finishing, pigments & dyes, beverages, and many more industries. We supply filter cloth for all makes and models of filter presses. Micronics is committed to providing you with great, high-performance filter cloth for your application – along with short lead-times and consistently on-time delivery performance!

Categories

Featured Posts

- Micronics Announces

Strategic Acquisition of

SOLAFT® Filtration Solutions - Chennai Office Inauguration

- Micronics Engineered Filtration Group Announces Strategic Acquisition of AFT®, Dry Filtration Solutions Leader, from FLSmidth

- The Power of Teamwork

- Building a High-Performance Team: Key Factors for Success

- Micronics’ CEO, Chris Cummins, Is Featured On “Manufacturing Excellence” Podcast

- Micronics Announces Large, Multi-plant Filter Press Order for Lithium-Ion Battery Recycling for EVs

- Micronics Engineered Filtration Group Announces Strategic Acquisition of Trusted Filtration Industry Leader, National Filter Media (“NFM”)

Contact Our Experts

Micronics Is Your Trusted Partner for Total Engineered Filtration Solutions. We offer end-to-end solutions from Filter Media to Industry-Leading Filtration Equipment, to Spare Parts & Accessories, to On-Site Field Services and In-House Laboratory Services. Whether for your Filter Press, Belt Press, Leaf Filter, Vacuum Filter, or Baghouse, you can count on Micronics’ deep industry and applications knowledge for the right engineered filtration solution to meet your needs. We look forward to working with your team.