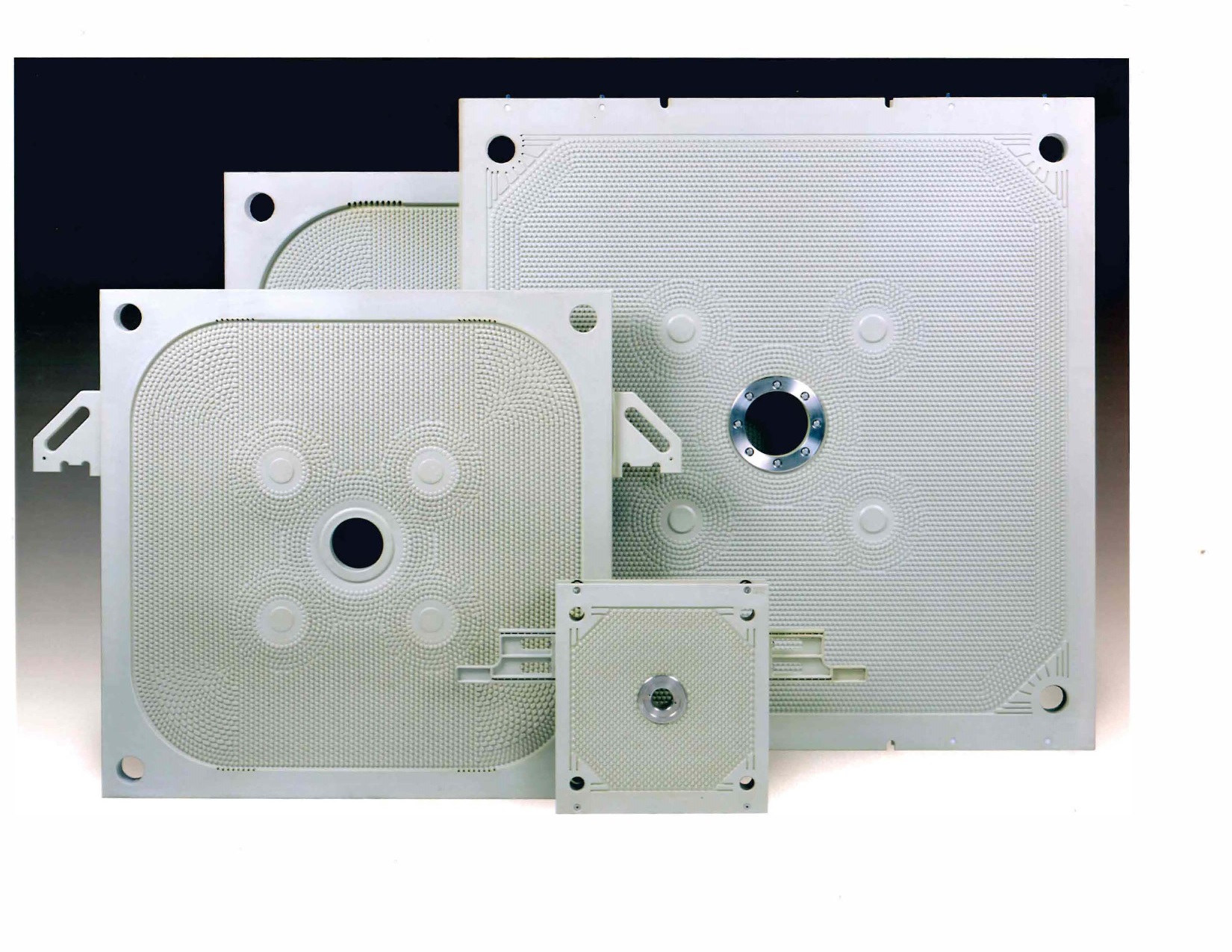

Micronics, Inc. offers a wide selection of filter press plates which – together with proper filter cloth selection and filter press specifications – can provide optimized dewatering for a variety of industries and applications. When faster filter press cycle time is desired, the choice of filter plates can play an important role.

Benefits of Mixed Pack Membrane Filter Plates

Contact Our Experts

Micronics Is Your Trusted Partner for Total Engineered Filtration Solutions. We offer end-to-end solutions from Filter Media to Industry-Leading Filtration Equipment, to Spare Parts & Accessories, to On-Site Field Services and In-House Laboratory Services. Whether for your Filter Press, Belt Press, Leaf Filter, Vacuum Filter, or Baghouse, you can count on Micronics’ deep industry and applications knowledge for the right engineered filtration solution to meet your needs. We look forward to working with your team.