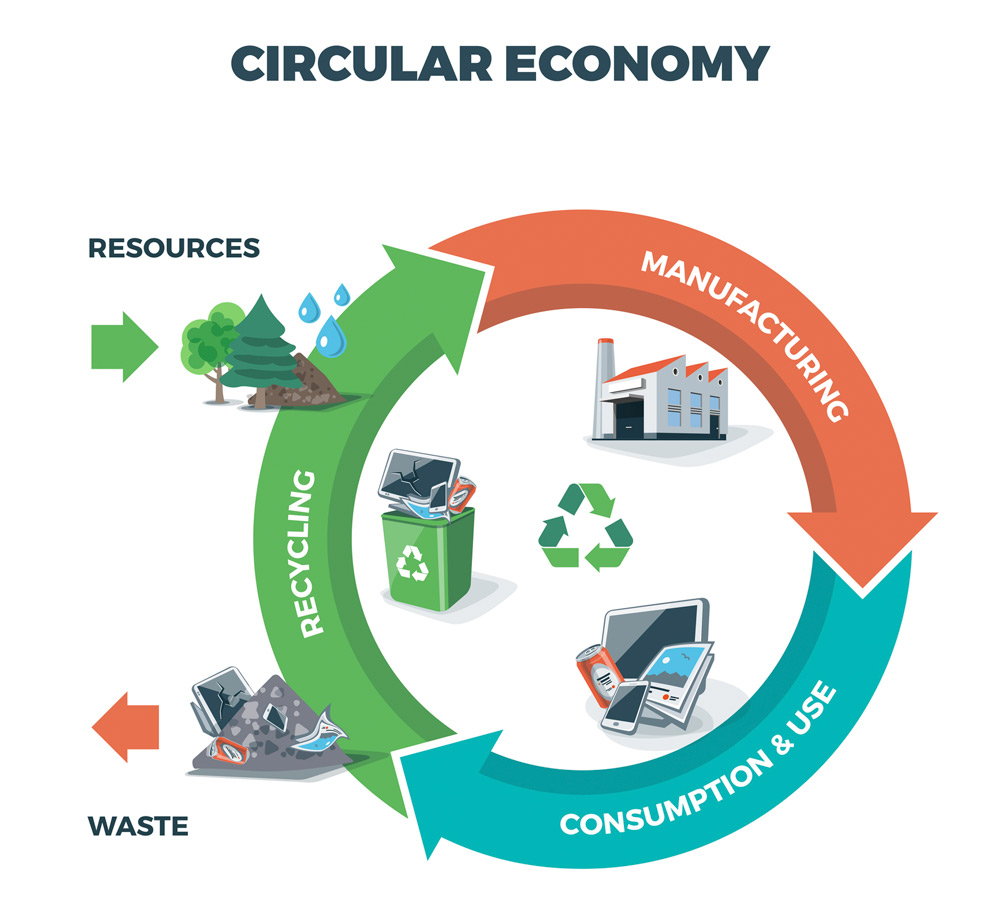

In the circular economy, the reuse of raw materials is optimized so that at the end of a product’s life cycle, many of the resources used to create it are recovered, recycled, and reused.

This is in contrast to a linear economy with a take-make-dispose system.

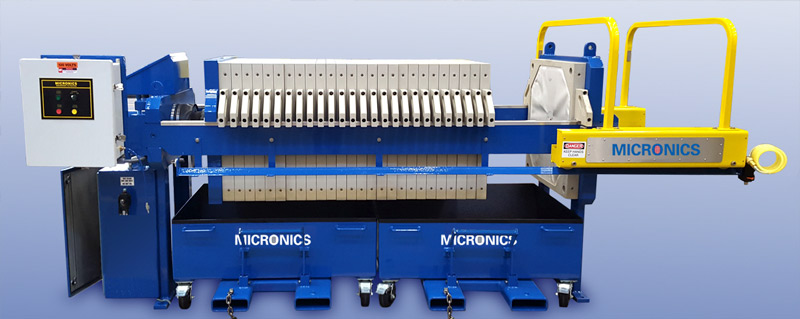

In this blog, we explore Filter Press Solutions from the Micronics Engineered Filtration Group including the MicroPress, our innovative Bench-Scale 150 mm Filter Press, for pilot testing. Read more below.