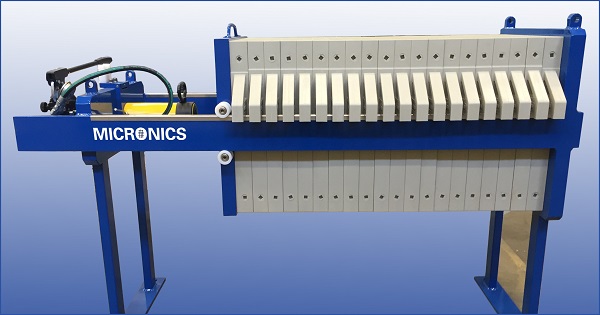

August 21, 2018 – Micronics is pleased to introduce two 470mm standard filter press models and six 630mm standard filter press models in the 1 cubic ft. up to 10 cubic ft. range. Micronics’ new standard press (MSP) models are cost-effective, reliable, and easy to operate & maintain. Our new filter press models address needs for reliability & quick turnaround!

Micronics Introduces New Standard 630mm and 470mm Manual Filter Press Models

Home > Micronics Introduces New Standard 630mm and 470mm Manual Filter Press Models

MSPs in the 470mm and 630mm range are perfect for manual dewatering operations and come with manual filter plate shifting, hydraulic hand pumps, and piping manifold with manual valves for controlling feed, filtrate, and cake blow. Micronics’ new MSP models are designed to get customers with small-medium capacity needs on the road to dewatering, quicker. These models are well-suited to a variety of markets including metal/surface finishing, metal plating, water treatment system OEMs, entry-level press owners, smaller companies, and small resellers.

MSPs in the 470mm and 630mm range are perfect for manual dewatering operations and come with manual filter plate shifting, hydraulic hand pumps, and piping manifold with manual valves for controlling feed, filtrate, and cake blow. Micronics’ new MSP models are designed to get customers with small-medium capacity needs on the road to dewatering, quicker. These models are well-suited to a variety of markets including metal/surface finishing, metal plating, water treatment system OEMs, entry-level press owners, smaller companies, and small resellers.

“Micronics is very pleased to introduce its new in-stock and ready-to-ship 470mm and 630mm press models. These standard products are designed based on customer feedback and represent Micronics’ commitment to offering customers with smaller capacity needs reliable dewatering solutions where very fast delivery is critical,” according to Marketing Director, Francine Bernitz.

Bernitz added, “Micronics will continue to excel in providing industry-leading custom and specialty filter press solutions – from small to large capacity – across a range of diverse applications. We are continually innovating in our broad press product range to best serve customers’ filtration needs.”

Standard Options for both the 470mm and 630mm Manual Filter Presses include:

- Air Operated (AOD) Feed Pump

- Automatic Feed Pump Control System (for control of the Air-operated Diaphragm Feed Pump)

- Cake Carts – to remove filter cakes for disposal. Ergonomically designed with swivel casters and forklift lifting points.

Micronics’ 470mm and 630mm manual filter press models are in-stock and ready-to-ship. They come complete with gasketed “CGR” filter plates and Micronics’ own high-quality, precision-manufactured filter cloth.

Please contact us, call us at 866.481.3694, or contact your local Micronics Regional Sales Manager to get a filter press quotation for these models.

About the Micronics Engineered Filtration Group

The Micronics Engineered Filtration Group consists of leading wet and dry engineered filtration brands including Micronics, Southern Filter Media, C.P. Environmental, United Process Control along with the AeroPulse® brand of APC equipment. The Micronics Engineered Filtration Group is an expert in Filter Press Solutions and Baghouse Solutions.

Incorporated in 1983, Micronics has been a portfolio company of Vance Street Capital, a Los Angeles-based private equity firm, since 2013. In late 2014, Micronics expanded into dry filtration and air pollution control products and services with the acquisition of Southern Filter Media (SFM). C.P. Environmental (CPE), United Process Control (UPC), and AeroPulse joined the Micronics Engineered Filtration Group in 2015.

The Micronics Engineered Filtration Group collectively serve customers’ filtration needs in mining and mineral processing; energy, power generation; industrial; chemical manufacturing; pigments and dyes; food and beverage; steel and iron processing; aggregates, cement, and asphalt; pharmaceutical & biotechnology; and water/wastewater treatment. The company’s tagline underscores its breadth and capabilities: Single Source for Filter Press and Air Pollution Control Needs.

We are committed to our customers’ success.

Contact:

Francine S. Bernitz

Marketing Director, Micronics Engineered Filtration Group

Francine.Bernitz@Micronicsinc.com

781.789.3178

Categories

Featured Posts

- Micronics Announces

Strategic Acquisition of

SOLAFT® Filtration Solutions - Chennai Office Inauguration

- Micronics Engineered Filtration Group Announces Strategic Acquisition of AFT®, Dry Filtration Solutions Leader, from FLSmidth

- The Power of Teamwork

- Building a High-Performance Team: Key Factors for Success

- Micronics’ CEO, Chris Cummins, Is Featured On “Manufacturing Excellence” Podcast

- Micronics Announces Large, Multi-plant Filter Press Order for Lithium-Ion Battery Recycling for EVs

- Micronics Engineered Filtration Group Announces Strategic Acquisition of Trusted Filtration Industry Leader, National Filter Media (“NFM”)

Contact Our Experts

Micronics Is Your Trusted Partner for Total Engineered Filtration Solutions. We offer end-to-end solutions from Filter Media to Industry-Leading Filtration Equipment, to Spare Parts & Accessories, to On-Site Field Services and In-House Laboratory Services. Whether for your Filter Press, Belt Press, Leaf Filter, Vacuum Filter, or Baghouse, you can count on Micronics’ deep industry and applications knowledge for the right engineered filtration solution to meet your needs. We look forward to working with your team.