Lock-Out/Tag-Out – also known as LOTO – is vital to the safety of your personnel and your machinery during Routine Maintenance. Lock-Out/Tag-Out is a safety procedure used to ensure that machines are properly shut off and not able to be started up again prior to the completion of maintenance or repair work.

Lock-Out/Tag-Out Systems are important in workplaces with Filter Press Equipment. LOTO is critically important for preventing equipment from being energized during routine filter press repairs or maintenance.

In this month’s blog post, Micronics focuses on the 6 Key Steps for a Proper Lock-Out/Tag-Out Procedure. Lock-Out/Tag-Out is proven to save lives! Please see your supervisor or your company’s safety coordinator for your company’s LOTO procedures and learn more or refresh your knowledge here.

Micronics’ Service professionals are the best in the filtration industry, and we are always happy to help our clients ensure the best, safest processes & procedures.

Most Micronics Filter Presses can be de-energized by turning off the main power supply to the 3 Phase Power Panel. Micronics Power Panels are supplied with a lockable on/off switch. However, it is recommended to Lock-Out the main power disconnect, supplying power to the filter press.

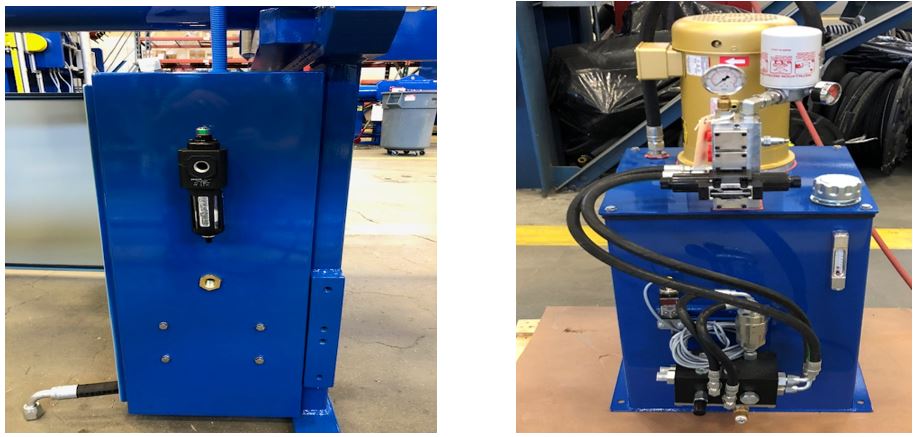

Most Micronics Filter Presses can be de-energized by turning off the main power supply to the 3 Phase Power Panel. Micronics Power Panels are supplied with a lockable on/off switch. However, it is recommended to Lock-Out the main power disconnect, supplying power to the filter press. Depending on your plant’s plumbing, air lines should be turned off. End-users are responsible for supplying shut-off valves for Micronics Pneumatic Filter Presses. Valve locks should be installed for pneumatic valves.

Depending on your plant’s plumbing, air lines should be turned off. End-users are responsible for supplying shut-off valves for Micronics Pneumatic Filter Presses. Valve locks should be installed for pneumatic valves.