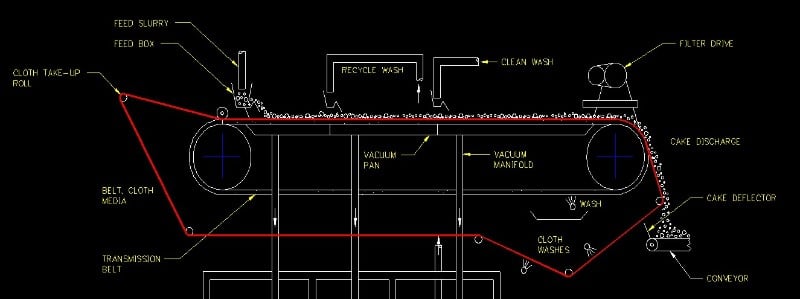

Horizontal Belt Vacuum Filters (HBVFs) perform well in applications that require cake washing. In a single run from slurry to dewatered cake, an HBVF can wash in multiple stages using counter-current flood washing to allow for the removal/recovery of the finest particles.

Some of the benefits of HVBFs over Rotary Drum Vacuum Filters (RDVFs) and Rotary Disc Vacuum Filters are visibility and reduced slurry inventory. Filtration from feed box to cake discharge can be seen on a Horizontal Belt Vacuum Filter. Since there is an overhead feed box instead of a slurry tank, the only slurry needed to operate is the slurry that will be filtered.

Common applications for HBVFs are mineral processing, gypsum, pharmaceuticals, and catalysts. Learn more about HBVFs below.