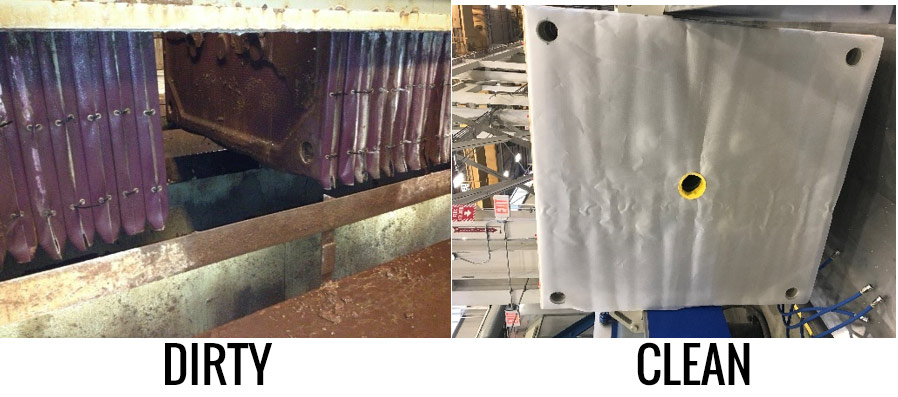

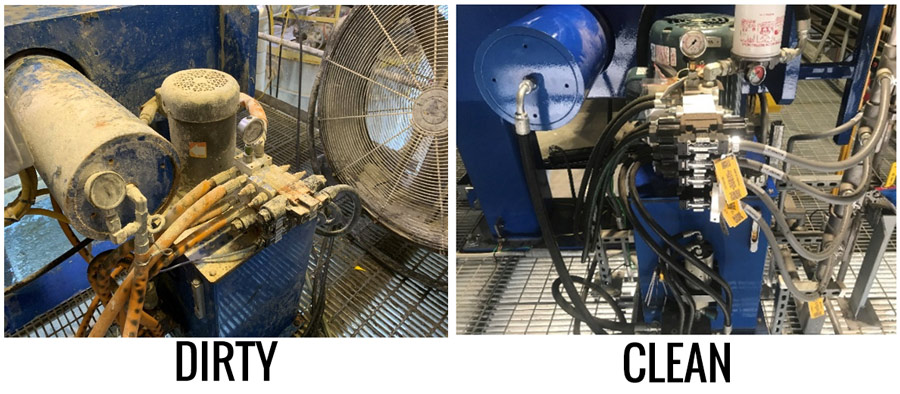

Along with regularly scheduled maintenance, good housekeeping is a vital ingredient to the overall performance of your Filter Press.

Dirty work areas not only cause safety concerns, but solids that may not completely exit the Filter Press during filter cake drop can cause operating concerns, maintenance issues, and budgetary setbacks.

Learn more below in this informative technical blog and let’s start the year off on a great footing!