Your baghouse is an investment in your operation and the Micronics Engineered Filtration Group – and trusted brands NFM, Filterfab, CPE, UPC, and SFM – recommends that you protect and pre-condition the filter bags and cartridges in your baghouse system with something that will enhance your investment. Precoat filter aid is just that.

Benefits of Using Precoat Filter Aid in Your Baghouse?

Home > Benefits of Using Precoat Filter Aid in Your Baghouse?

What is Precoat Filter Aid?

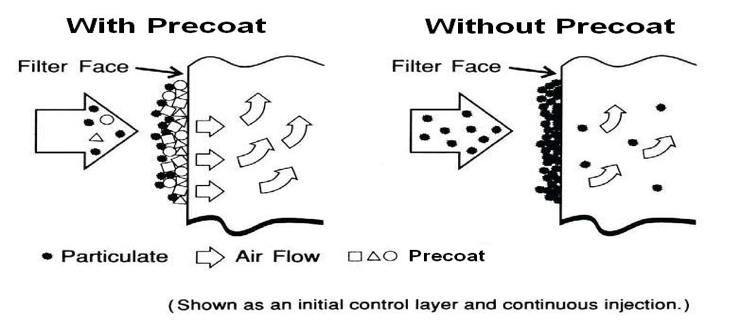

Precoat or precoat filter aid is a dry, chemically-inert, non-toxic, and easy-to-use powder that may be used to coat and condition the fabric filters in your baghouse to improve filtration efficiency and effectiveness. Think of it as an aid or enhancer to the formation of a uniform, three-dimensional, porous dust cake in your baghouse.

Precoat Benefits

Precoat has a naturally well-balanced particle size distribution that promotes increased airflow and aids collection efficiencies, resulting in reduced differential pressure and lower energy costs. The use of the precoat filter aid also enhances fabric filter bag life, protecting the fabric from blinding and plugging, Clients are always looking for tips to improve efficiencies and reduce operating & maintenance costs and this is one tool to consider. Since precoat has a high melting point, it can also inhibit damaging sparks when used as a control layer.

To summarize, the key benefits of using our precoat filter aid in your baghouse include:

- Enhances fabric filter bag life and performance

- Protects fabric from blinding and plugging

- Increases air flow

- Decreases differential pressure

- Aids dust collection efficiencies

- Inhibits damaging sparks

- Will absorb damaging moisture, oils, and hydrocarbons

- Lowers O&M costs

Precoat Coverage: A Rule of Thumb

One pound of Precoat Filter Aid will effectively cover over 22 square feel of cloth with a 1/16” coating.

Precoat Alternatives

Lime and fly ash have been used for years to pre-condition fabric filters. Lime is alkaline and in the presence of moisture will agglomerate, causing filter plugging and increased differential pressure. In addition, lime consists of particles of very similar shape and size, thus creating a cake that is dense and compact, which will result in higher airflow resistance.

Because lime has a heavier bulk density than our precoat filter aid, it will only cover 3 square feet of cloth per pound, thus requiring large amounts to complete the job.

Fly ash is also heavier in bulk density than our precoat filter aid and is also abrasive. Depending on the type of fly ash purchased, it can range from being extremely acidic to highly basic. Fly ash is extremely heavy and may even fall off the fabric filter while under pressure. This means that most the “aid” will end up in the hopper instead of on the fabric.

Compared to our precoat filter aid, fly ash will only cover 4 square feet of cloth per pound, hardly giving an economical advantage.

Precoat Usage Example & Formula

The precoat-to-cloth ratio is 0.042 lbs. of precoat per square foot of cloth.

Example: The collector has 1680 bags. Each bag is 6” x 169”

Calculation:

- (6 * π) *169 = 3185 square inches/bag

- 1 square foot = 144 square inches

- 3185 square inches per bag/ 144 square inches per foot = 22.12 square ft. per bag

- 22.12 square feet per bag * 1680 bags = 37,162 square feet of cloth for the baghouse system

- 37,162 square feet of cloth * .042 lbs of Precoat per square foot of cloth = 1561 lbs. of Precoat Filter Aid needed to treat this Pulse Jet baghouse.

The Micronics Engineered Filtration Group’s baghouse experts will help you with these and other tips to operate an efficient, cost-effective, and compliant baghouse.

Contact us and request a quote on precoat filter aid, and our Baghouse Maintenance & Repair services, preventative maintenance programs, and filter media options. Let our experts help you in improving baghouse efficiency and effectiveness and meeting and maintaining compliance.

Categories

Featured Posts

- Micronics Announces

Strategic Acquisition of

SOLAFT® Filtration Solutions - Chennai Office Inauguration

- Micronics Engineered Filtration Group Announces Strategic Acquisition of AFT®, Dry Filtration Solutions Leader, from FLSmidth

- The Power of Teamwork

- Building a High-Performance Team: Key Factors for Success

- Micronics’ CEO, Chris Cummins, Is Featured On “Manufacturing Excellence” Podcast

- Micronics Announces Large, Multi-plant Filter Press Order for Lithium-Ion Battery Recycling for EVs

- Micronics Engineered Filtration Group Announces Strategic Acquisition of Trusted Filtration Industry Leader, National Filter Media (“NFM”)

Contact Our Experts

Micronics Is Your Trusted Partner for Total Engineered Filtration Solutions. We offer end-to-end solutions from Filter Media to Industry-Leading Filtration Equipment, to Spare Parts & Accessories, to On-Site Field Services and In-House Laboratory Services. Whether for your Filter Press, Belt Press, Leaf Filter, Vacuum Filter, or Baghouse, you can count on Micronics’ deep industry and applications knowledge for the right engineered filtration solution to meet your needs. We look forward to working with your team.