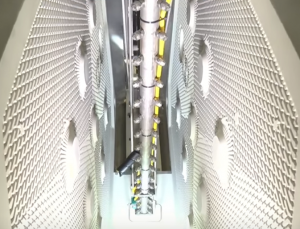

Did You Know…To prolong the life of your Filter Press Cloth, Micronics offers a Filter Press Fully Automatic Filter Cloth Washer. Micronics’ low profile Automatic Cloth Washing System allows the filter cloth/filter plates to be quickly and efficiently washed on a regular basis yet without time-consuming, operator-intensive manual cleaning efforts, a real productivity & efficiency boost for today’s demanding Filter Press operations.

NEW: While these Fully-Automatic Filter Cloth Washing Systems are typically used for 1500mm Filter Presses and larger, Micronics is pleased to announce that, through our Engineering team’s innovative work, we can provide our Fully-Automatic Filter Cloth Wash Systems now for 1200mm Filter Presses as well!

Learn more about the Micronics Automatic Cloth Washing System in the blog content below.