You know that filter cloth is the key ingredient to an efficient, effective filter press operation. Proper filter cloth selection & proper cloth fit are leading reasons to work with the Micronics Engineered Filtration Group. Here are 7 more reasons to Buy Micronics Filter Cloth.

1. We offer the deep insights that come from both Filter Cloth & Engineered Filtration Equipment design and manufacture. Some suppliers have textile expertise. Others have equipment expertise. Few have the complete understanding of the filter press, feed pump system, and textile knowledge from weave to finish. For optimal press operation, you really need a supplier who can envision and diagnose the complete filtration solution including fabric design, feed pump method of control, etc. That is Micronics Engineered Filtration.

1. We offer the deep insights that come from both Filter Cloth & Engineered Filtration Equipment design and manufacture. Some suppliers have textile expertise. Others have equipment expertise. Few have the complete understanding of the filter press, feed pump system, and textile knowledge from weave to finish. For optimal press operation, you really need a supplier who can envision and diagnose the complete filtration solution including fabric design, feed pump method of control, etc. That is Micronics Engineered Filtration.

2. Speedy Cloth Quotes. Micronics can typically provide you with same day filter cloth recommendations and filter cloth quotations. We are constantly working to be more responsive and provide you with quotes faster.

2. Speedy Cloth Quotes. Micronics can typically provide you with same day filter cloth recommendations and filter cloth quotations. We are constantly working to be more responsive and provide you with quotes faster.

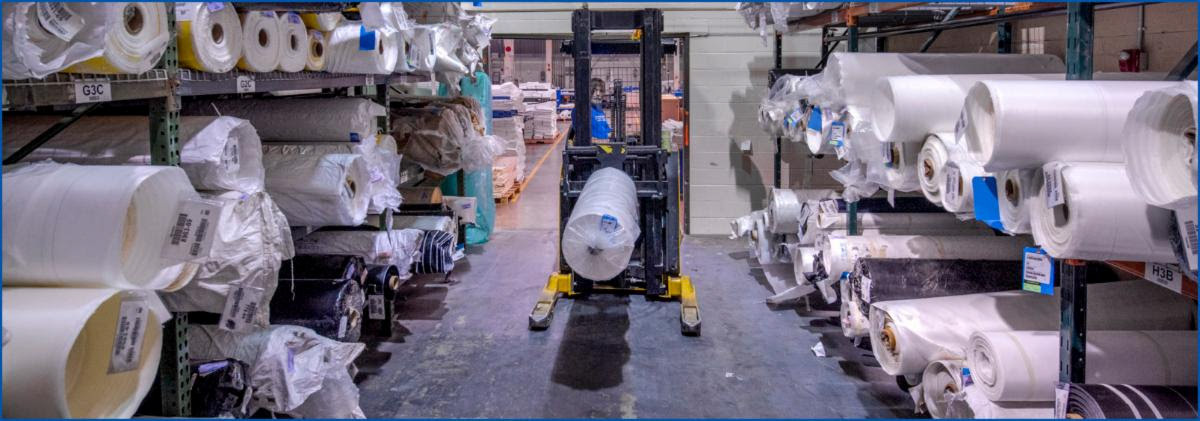

3. Best Lead Times. We are proud of our industry-leading lead times and we are constantly working to improve to best serve your plant’s needs. We know you are sometimes in a bind due to an unplanned failure and, assuming your material is in our inventory, we can often expedite production and shipment within 24 hours. Our goal is always to help you maximize press up-time higher productivity & for lower operating costs. We like to ascribe to what Vince Lombardi said: “Perfection is not attainable. But if we chase perfection, we can catch excellence.”

4. Inventory Management for Planned and Unplanned Cloth Changeouts. We partner with our clients to ensure you are stocked and ready for your planned cloth changeouts. We will also help you to prepare for premature, unanticipated cloth failures because…things happen. In mining, even the most well-suited filter cloths may fail prematurely if there is a very high percentage of clay in the mine tailings, just as one example.

5. “HPR” Rubber Necks for Improved Performance. Lots of suppliers talk about barrel necks but did you know that Micronics produces genuine welded feednecks for proven superior performance? The rest of the barrel necks are simply not the same, irrespective of what they say.

5. “HPR” Rubber Necks for Improved Performance. Lots of suppliers talk about barrel necks but did you know that Micronics produces genuine welded feednecks for proven superior performance? The rest of the barrel necks are simply not the same, irrespective of what they say.

6. Free of Charge (FOC) Samples for Testing. Not only do we provide the best cloth in full production runs but as you are exploring a new process, sizing a new press, or changing from another filter cloth supplier, we will provide you with FOC cloth samples to optimize cloth selection. We don’t want the filter cloth to be simply “OK” but the best choice for your requirements.

7. In-House Lab Testing. Micronics’ new Chattanooga HQ is home to a new Lab Testing facility where we can fully examine your filter media to better understand failures, conduct bench-scale pilot testing on your slurries, target filter cloth improvements, and more.

Contact us to benefit from Micronics Filter Cloth advantages.

Categories

Featured Posts

- Micronics Announces

Strategic Acquisition of

SOLAFT® Filtration Solutions - Chennai Office Inauguration

- Micronics Engineered Filtration Group Announces Strategic Acquisition of AFT®, Dry Filtration Solutions Leader, from FLSmidth

- The Power of Teamwork

- Building a High-Performance Team: Key Factors for Success

- Micronics’ CEO, Chris Cummins, Is Featured On “Manufacturing Excellence” Podcast

- Micronics Announces Large, Multi-plant Filter Press Order for Lithium-Ion Battery Recycling for EVs

- Micronics Engineered Filtration Group Announces Strategic Acquisition of Trusted Filtration Industry Leader, National Filter Media (“NFM”)

Contact Our Experts

Micronics Is Your Trusted Partner for Total Engineered Filtration Solutions. We offer end-to-end solutions from Filter Media to Industry-Leading Filtration Equipment, to Spare Parts & Accessories, to On-Site Field Services and In-House Laboratory Services. Whether for your Filter Press, Belt Press, Leaf Filter, Vacuum Filter, or Baghouse, you can count on Micronics’ deep industry and applications knowledge for the right engineered filtration solution to meet your needs. We look forward to working with your team.