Micronics’ Dry Filtration Laboratory Testing Capabilities include:

Filter Bag Testing & Evaluation of Failed Filter Bags

Filter Bag Testing can be performed at various stages of a filter bag’s life. Micronics can evaluate a filter bag to provide a customer with insights into the bag’s Permeability, Mullen Burst, and Tensile Strength, providing valuable predictive information as to the useful life of the media and the number of months or years left of baghouse service.

Micronics can evaluate causes of failure in a client’s baghouse and make recommendations on a preferred filter media solution or filter bag construction, given application requirements and operating conditions.

Micronics personnel have extensive expertise in understanding the causes of bag failure and making recommendations for corrective action. Using filter bag testing, we can detect causes of emissions excursions, causes of premature filter bag failure, and causes of high differential pressure drop.

Analysis of filter bag failures by experienced personnel can often reveal system problems that, when corrected, will improve the operating condition of your baghouse, minimizing maintenance costs & maximizing your baghouse investment.

Permeability Testing

Micronics performs Permeability Testing to determine the air handling capability of filter media. Permeability, as defined by the Frazier number, is the volumetric flow rate measured in cfm through a square foot of filter media at a differential pressure of 0.5 w.g.

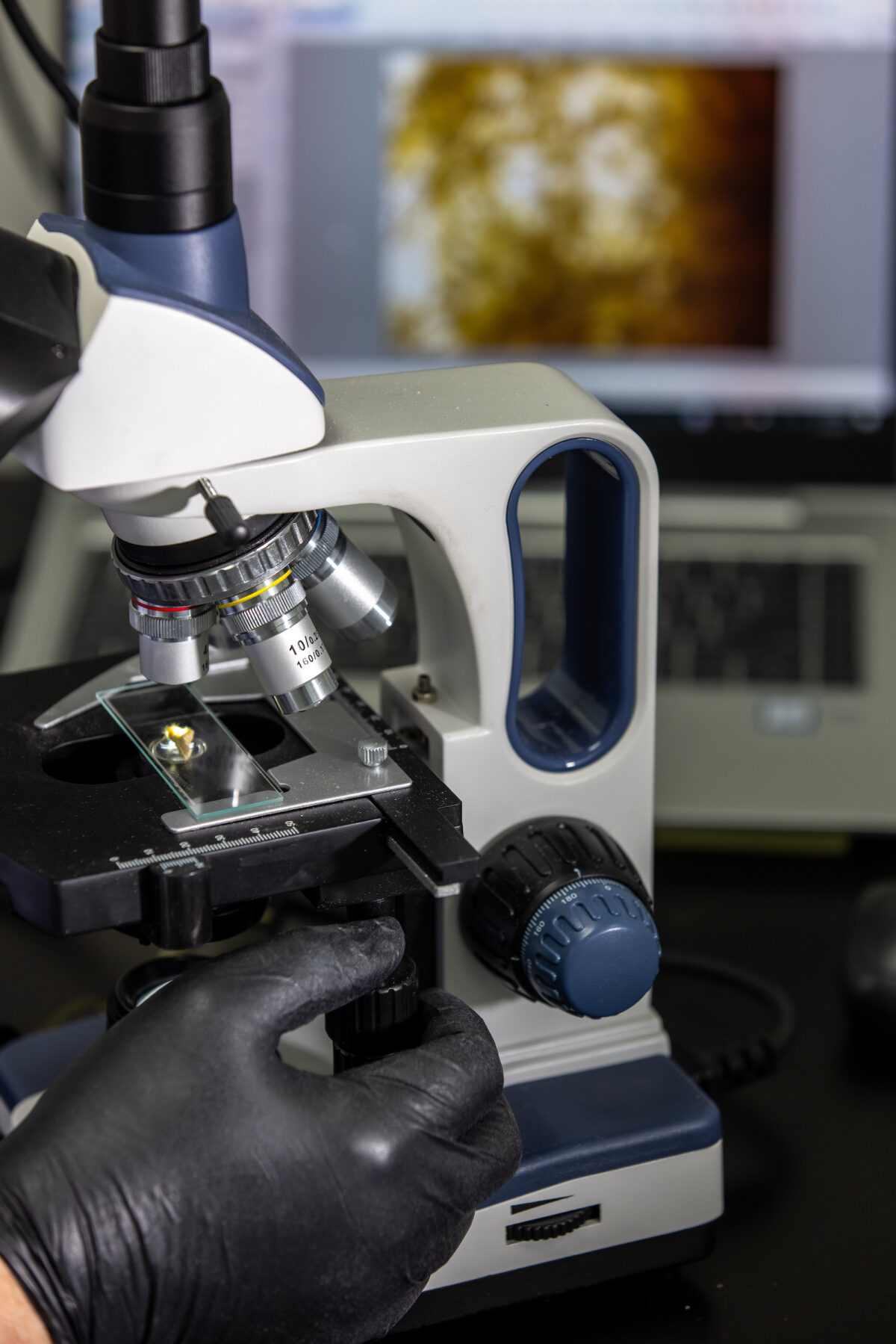

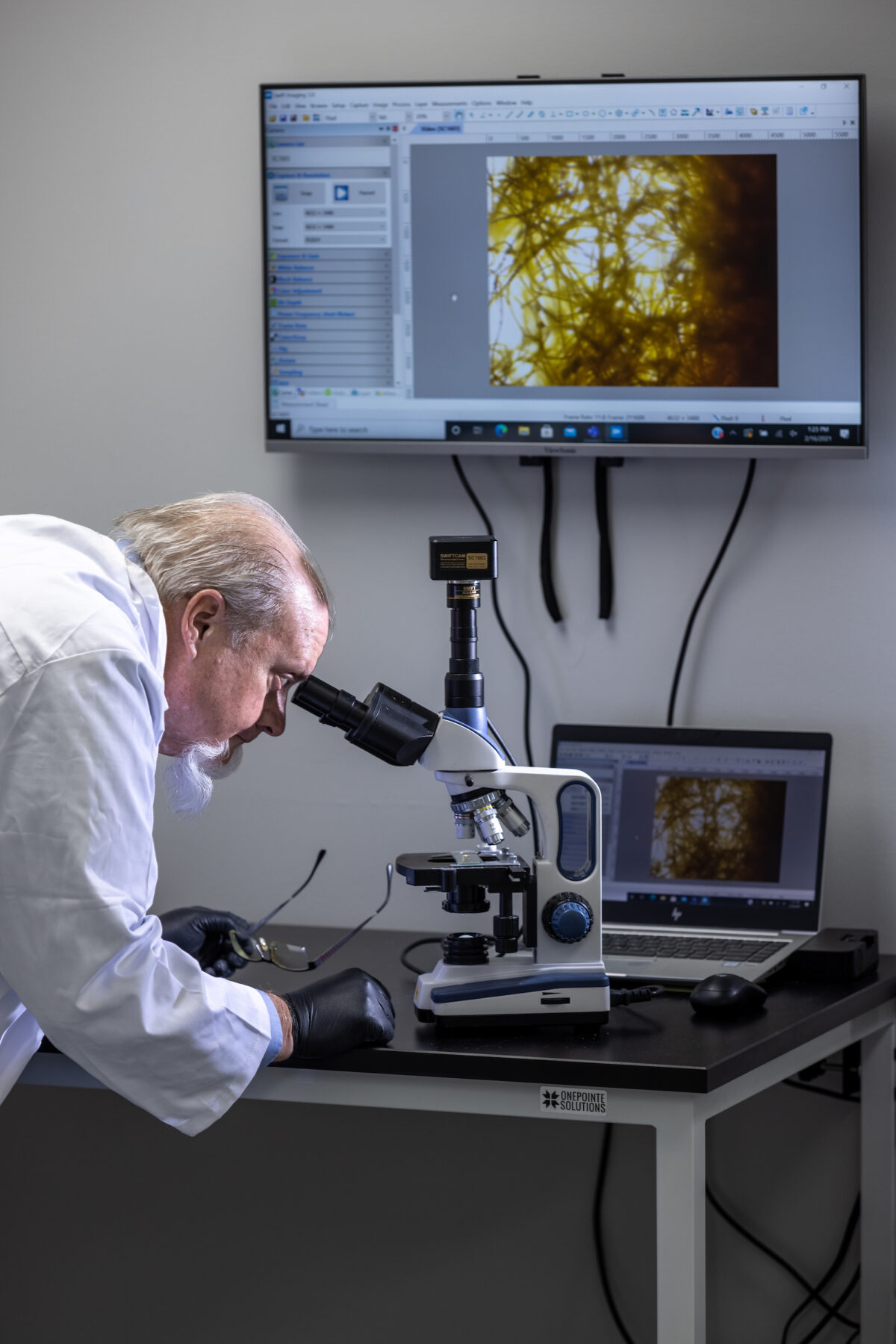

Visual/Microscopic Analysis

Micronics’ highly-experienced personnel perform full bag visual analysis of failed filter bags. It is very helpful in doing failure analysis to examine the dry particulate interaction with the filter media surface in order to determine causes of bag deterioration, bag blinding, and failure. We routinely make filter media and bag construction recommendations to more effectively deal with baghouse operating conditions which may include abrasion, presence of chemicals, hydrolysis, and temperature effects.

In addition to Micronics’ In-House Filter Bag Laboratory Testing capabilities, Micronics also offers In-House Liquid Filtration Testing Services, right in our Chattanooga location. Learn more here about Micronics’ In-House Liquid Filtration Testing capabilities for your company’s current or planned filter press projects.