In-House Laboratory Testing Capabilities that Micronics offers include:

Determining Best Filter Cloth for a Specific Customer Application

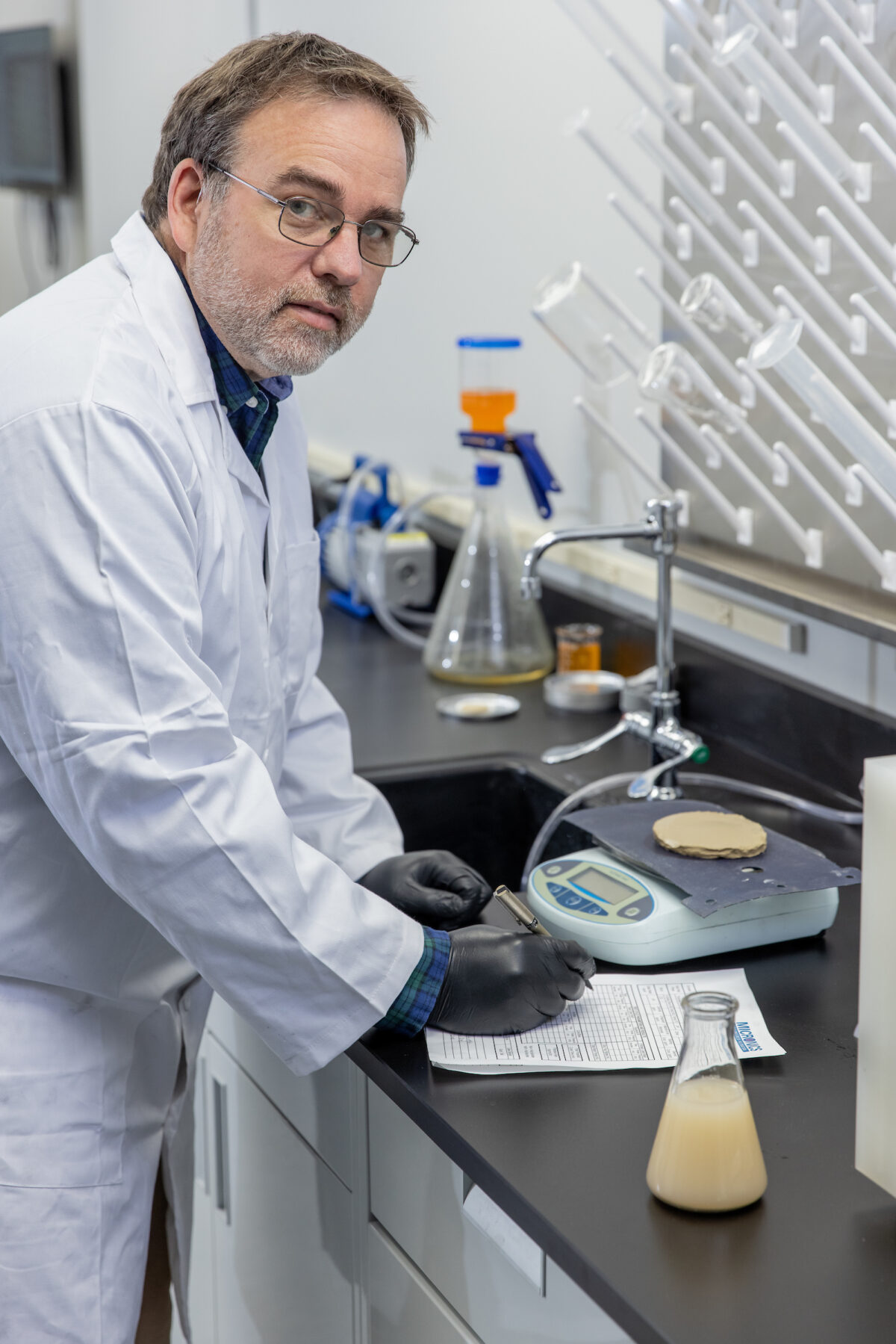

With Micronics’ In-House Laboratory Testing facilities, we are able to ensure the right filter press cloth is being recommended for each given application. Parameters that we evaluate in our laboratory include:

- Filtration characteristics

- Cake release

- Solids capture/filtrate quality

Micronics can also do a complete evaluation on customers’ existing filter cloth to provide a performance comparison vs. our proposed Micronics brand filter cloth recommendations.

Slurry Analysis including Determining % Feed Solids

Performing Filter Cake Analysis including:

- Determining filter cake % solids

- Determining filter cake % moisture

- Determining filter cake density

- Determining Cycle time

- Determining if standard recess chamber filtration or membrane squeeze is needed

Micronics works closely with customers to optimize their filter press operations, helping to reduce costs through lower moisture-content cakes. In instances where the filter cake is the waste, the lower the moisture content in the cakes, the lower the hauling costs. With press operations that produce high-solid cakes, the need for scraping and cleaning are minimized, saving customer operating teams on maintenance costs. Choosing the optimal filter cloth for your specific application is a key to getting excellent cake release, well-formed cakes, and lowering costs.

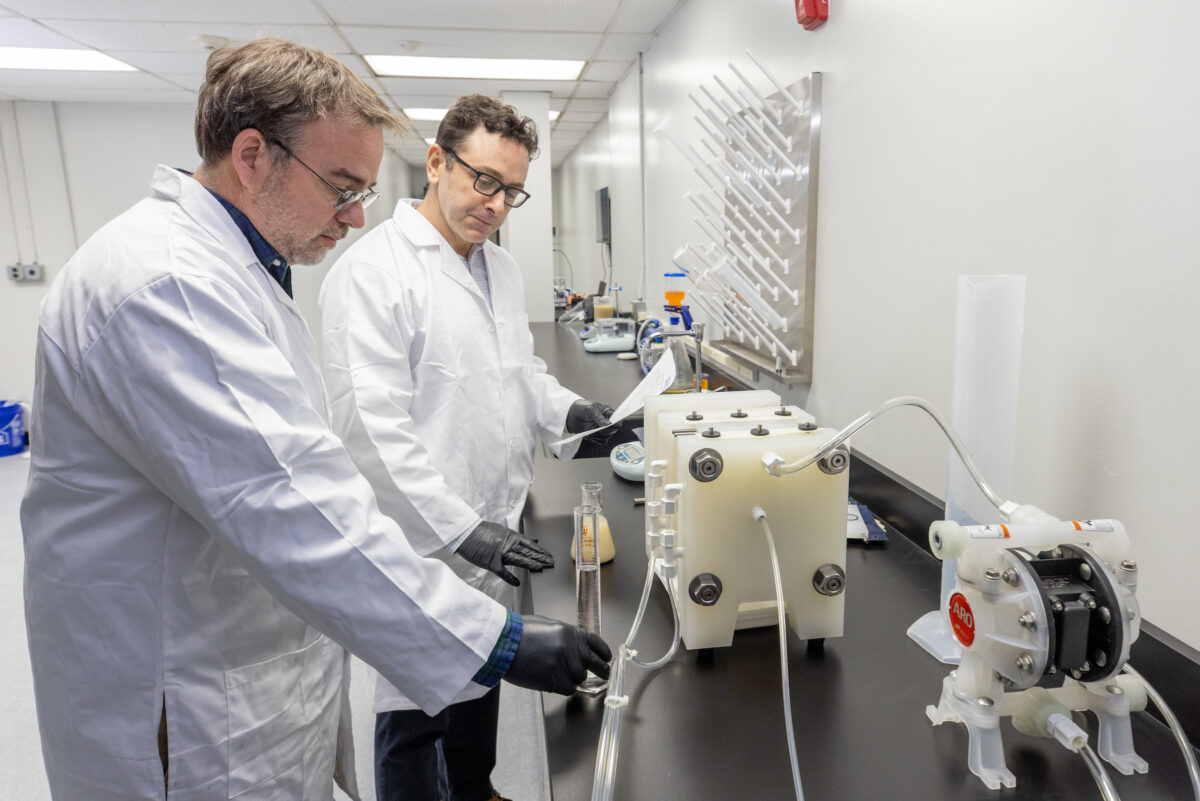

Using Micronics’ innovative MicroPress™ – its 150mm Industrial Bench-scale Filter Press – to determine a customer’s production-scale needs including:

- Determining Cycle Time

- Testing both 100 psi and 225 psi filter press applications

- Recessed Chamber and Membrane Squeeze capabilities

- Testing of Cake Blow capabilities for achieving potentially drier cakes

- Determining if Pre-coat or body feed is necessary to improve dewaterability

- Determining if Chemical Conditioning is necessary to improve dewaterability.

Micronics is able to perform multiple In-House Laboratory Tests to help to optimize a customer’s existing filter press system as well as perform tests to determine optimum press sizing for a customer’s future project.

Customers can also opt to purchase or rent Micronics’ 150mm bench-scale unit, the MicroPress™, and perform testing in their own facilities.

In addition to Micronics’ Liquid-Solid Separation In-House Laboratory Testing capabilities, Micronics also offers In-House Dry Filtration Testing Services, right in our Chattanooga location, as well as in our MS location.