Micronics has a long, proven track-record of providing exceptional filter presses to the Mining & Mineral Processing industries for Mine Tailings, Mineral Concentrates, and the Merrill-Crowe process.

In addition to its Micronics brand large filter presses, Micronics has been a trusted distributor for the LASTA-MC Mining Filter Press since 2009. Learn more about some of the details of the LASTA MC Filter Press here. The LASTA MC is a robust high-capacity solution for many mine tailings applications and typical press sizes are 2.1m x 2.1m.

With the Lasta MC, cake discharge is fully automatic and designed for 24-hour operation in a harsh environment. The design of the filter chamber and separation of the cloth from the plate actuates cake discharge; any momentarily held cakes are dislodged by the cloth drop mechanism. Any residual sticking filter cakes are sensed by the cloth hanger bar resting on the vibrator tube. This condition actuates a vibration frequency designed to discharge all remaining cakes.

With the Lasta MC, cake discharge is fully automatic and designed for 24-hour operation in a harsh environment. The design of the filter chamber and separation of the cloth from the plate actuates cake discharge; any momentarily held cakes are dislodged by the cloth drop mechanism. Any residual sticking filter cakes are sensed by the cloth hanger bar resting on the vibrator tube. This condition actuates a vibration frequency designed to discharge all remaining cakes.

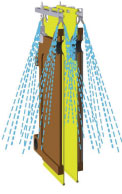

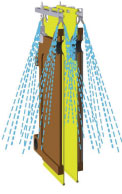

Cloth Washing – Fully Automatic and Rapid, < 1 minute

While cloth washing takes only ~30 seconds, it is one of the keys to economical, consistently high-volume filter press operations.

Cloth washing is application-specific and may be set for a total cloth wash:

- After each cake discharge cycle

- Rotating batches of cloth

- After a specific number of cycles for water conservation

A unique feed device, attached to the filter cloth, provides excellent concentrate delivery into the chamber and a protective rubber layer is used to ensure a high number of cycles before filter cloths require changing. This protection allows many more options for filter cloth designs to be selected.

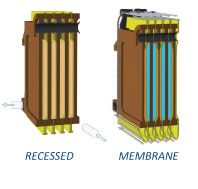

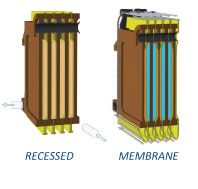

The LASTA MC filter press can be configured with either recessed filter plates or combination membrane/companion recessed filter plates.

Membrane squeeze plates provide the option for squeezing at high pressure and can be used to shorten the cycle time and/or consolidate the filter cake for more effective air blow results. In the case of membrane plates, additional equipment is required to provide high pressure water for squeezing.

Expert Service, Spare Parts and Application Support…When You Need It

A critical component of any filter press application is after-market service. Without technical support, even sophisticated filtration equipment can become both unreliable and expensive to maintain.

Ishigaki and Micronics have partnered to provide you with spare parts for the LASTA MC, expert field service, installation and commissioning support, and application assistance. With Micronics’ expert support, the LASTA MC will function as designed – efficient, cost-effective, and highly reliable for high-capacity filtration needs in rugged, demanding environments and remote locations.

Micronics has a wealth of knowledge and experience in the global Mining & Mineral Processing industry from which to draw upon.

With the Lasta MC, cake discharge is fully automatic and designed for 24-hour operation in a harsh environment. The design of the filter chamber and separation of the cloth from the plate actuates cake discharge; any momentarily held cakes are dislodged by the cloth drop mechanism. Any residual sticking filter cakes are sensed by the cloth hanger bar resting on the vibrator tube. This condition actuates a vibration frequency designed to discharge all remaining cakes.

With the Lasta MC, cake discharge is fully automatic and designed for 24-hour operation in a harsh environment. The design of the filter chamber and separation of the cloth from the plate actuates cake discharge; any momentarily held cakes are dislodged by the cloth drop mechanism. Any residual sticking filter cakes are sensed by the cloth hanger bar resting on the vibrator tube. This condition actuates a vibration frequency designed to discharge all remaining cakes.