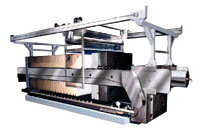

The Micronics Engineered Filtration Group designs and builds hundreds of different medium-capacity & high-capacity Filter Presses – Sidebar and Overhead Beam Presses- for various applications, including sludge dewatering and industrial water and wastewater filtration. Capacities include 1000mm, 1200mm, 1500mm, 1.5m x 2m, and 2m filter presses.

Our team of highly-skilled personnel engineer these specific filter press designs for filtering large slurry volumes.

Learn more about Sidebar and Overhead Beam filter press designs here.